The Kanban Pizza Game is a game created by agile42 that I often use in training to introduce Kanban. Indeed, unlike other workshops focusing on specific mechanics or concepts, it is a fun workshop, offering an incremental approach to learning and rather simple to animate. Here is a feedback from a session carried out at a client's for a group of 10 people. 🙂

The preparation

In terms of equipment, here is what you will need per group (4-6 people):

- Post-its in 3 different colors: yellow (pineapple), pink (ham/shrimp) and green (arugula)

- A4 sheets

- Red markers (I warn you, they will suffer)

- Glue

- painter's tape

- One or two pairs of scissors

- A stopwatch (or have participants use one of their phones)

- A set of orders

- A location of oven

- The slides of Kanban Pizza Game (Eng)

and don't forget your good mood! 😉

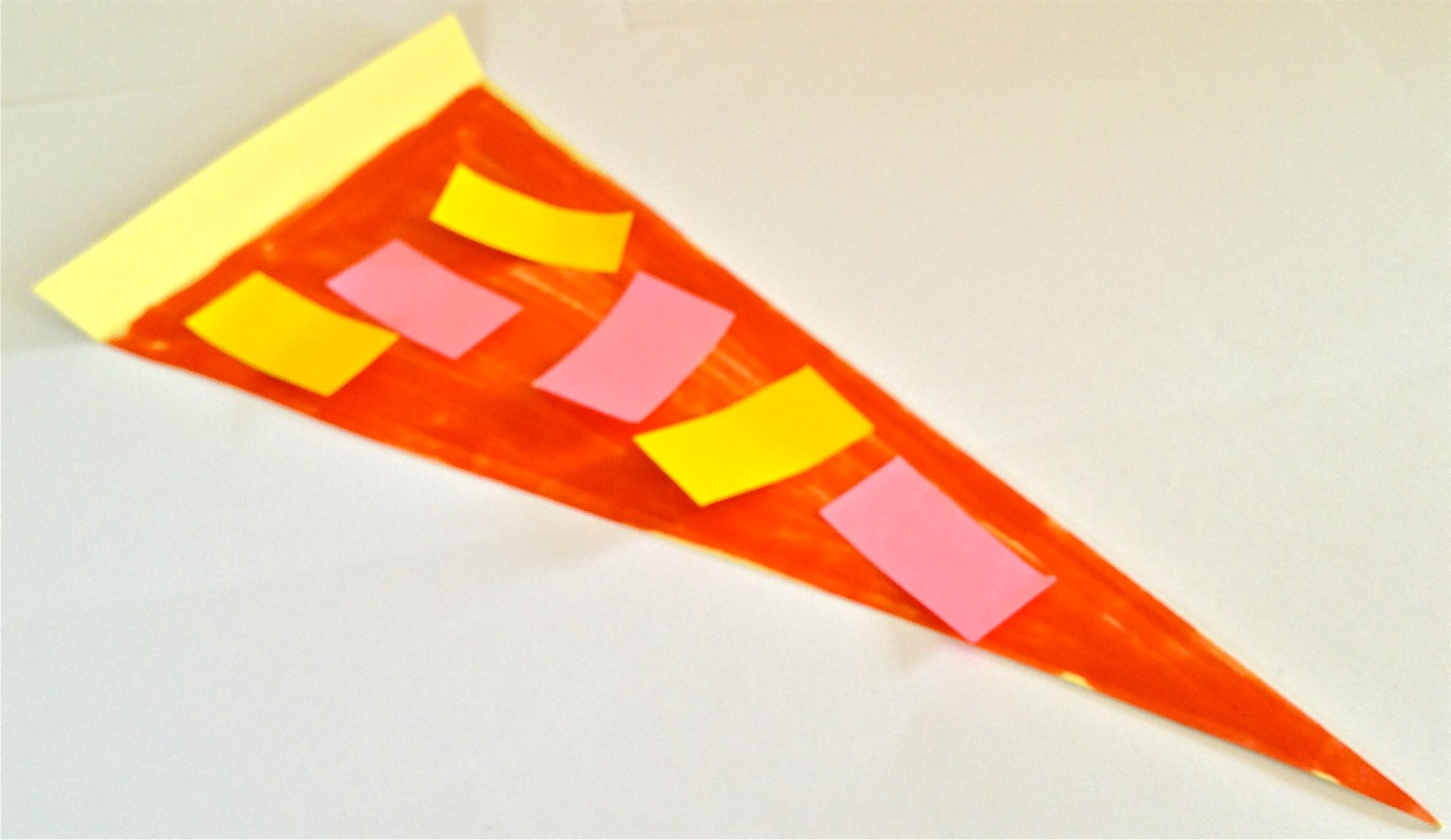

Note: Consider making a model pizza slice for the introduction to the workshop. I usually do this using half A4, which I then cut diagonally.

Intro to the workshop

The workshop taking place at noon, it was good, I announced to the participants:

Today, you open your pizzeria and who says pizzeria says pizzas! 🙂

The marked enthusiasm of the hungriest quickly died down when I showed them a model of what they were going to have to build:

The objective for you will therefore be to produce pizzas. For this, you will have 4 iterations + 1 synthesis iteration.

Note: You may be asked how long the iterations are. I then respond by saying that the iteration ends when I choose to, with a clap or with background music. The hidden objective is to prevent participants from changing their behavior according to the amount of time they have left, but rather to put in place a strategy keeping in mind that at any time the iteration can stop. Just for us, we know that the iteration lasts between 5-7 minutes! 😉

When you lead a workshop, don't forget that you are responsible for the framework! 🙂

The 4 Kanban principles

Unless I'm mistaken, I don't believe this appears in the initial Kanban Pizza Game workshop, but I like to do a quick run through the Kanban principles before starting the workshop.

Start where we are

The goal is not to reinvent the wheel. Today there is a process that makes it possible to produce value – with its advantages and disadvantages – and that is where we start. Kanban is qualified as a meta-process (meta comes from the Greek meaning “after, beyond, with”), ie it only needs to be applied to another process. Not disrupting the existing in the first place can be less disruptive for team members.

Initially, respect the process, roles and responsibilities

The second principle suggests that change is made with respect for the organization, especially the roles and responsibilities of people. The whole nuance is in the “Initially”. We then have the freedom afterwards to change these roles if we feel the need to do so.

Commit to incremental and scalable change

The third principle indicates that change with Kanban is done step by step, based on learning acquired over time. Each evolution is then an operational version usable by its users. We often hear that Kanban is an intention of continuous improvement, which induces the notion of experimentation and necessarily the right to make mistakes.

Encourage acts of leadership at all levels

Every person, regardless of status, can have a good idea to improve the process. It is by encouraging individual and collective initiatives that we promote the continuous improvement of the whole.

Course of the workshop

Round 1: Emergence of an implicit process

As the first Kanban principle indicates, we start where we are, that is to say with an existing process. The objective of this first round is therefore to bring out a process of the different teams which will be considered as their starting process.

It is time to describe a little more precisely this slice of pizza presented previously:

Here is a slice of Hawaiian pizza. As you can see, it is basic tomato (red marker) with 3 pieces of ham/shrimp (pink post-its) and 3 pieces of pineapple (yellow post-its). See how well the sauce covers the dough and the topping is well cut and distributed on the pizza. Yum ! 🙂

The important thing here is to clearly show what is expected, especially in terms of quality. This will be one of the levers on which you can act later in the workshop to accept / reject productions.

I then show the sheet representing the oven:

Here is the space reserved for the oven. Like any pizza professional, you must cook your pizza before delivering it to the customer. It is considered that it takes at least 30 seconds for a slice of pizza to be cooked and that a maximum of 3 slices can be put on simultaneously. Be careful, when cooking is underway, there is no longer any possibility of adding or removing parts, it would be a shame to burn yourself! :-p

Then I describe the goal of the iteration:

It's the opening of the store and you have people at the entrance. Produce the maximum number of pizza slices while avoiding the waste of unused ingredients – indeed, you don't have a lot of cash! I will indicate the end of the iteration to you by clapping my hands.

I quietly watch the production process emerge from the team and then stop the iteration after 5-7 minutes.

Explanation of the point system

The point system is the sinews of war and will allow the different teams to evaluate and improve. It was defined in such a way as to reward finished products (part of pizza cooked with all the ingredients) and to punish waste (ingredients prepared but not used).

So :

- For each remaining pizza base, you lose 4 points,

- For each remaining ingredient, you lose 1 point,

- For each finished slice of pizza, you earn 10 points.

Generally, this is when there is an outcry!

But we didn't know there was this point system!

And it's true, they didn't know it! It was the goal ! :-p But as often, it is in the frustration that we learn and that we produce the most beautiful improvements! 😉

Then comes the counting of points, which turns out to be not without teasing from the different teams, especially when their result is negative. Everything is then displayed on a sheet of flipchart.

| Team A | Team B | |

| Round 1 | 18 | -12 |

| Round 2 | ||

| Round 3 | ||

| Round 4 |

The 6 Kanban practices

After counting the points, comes the time to introduce the 6 Kanban practices. Without going into too many details, the important thing is to give the participants some lines of thought and get them to act accordingly. (I remind you that this workshop is made to live the Kanban experience!)

View the stream

- Did you have a workflow?

Limit work in progress

- Were there places where your ingredients piled up and turned into waste?

- What would be a good limit for this step? And the others ?

Measure and manage flow

The measurement here is done through the points system which rewards the production of finished items and punishes waste related to the process.

Make the rules of the process explicit

- Enable people to do the right things in the right way and above all at the right time!

- The clearer the rules, the less time you waste asking questions

Implement feedback loops

- Do you regularly review your work and your process?

- Do retrospectives, stand-ups...

Improve collaboratively, Evolve experimentally

- Using scientific metrics and models to continuously improve

Round 2: a Kanban system

After this quick introduction to the 6 Kanban practices, it was time to put them in motion:

You have 5 minutes to build your workstations by introducing storage places for ingredients, for example using the painter's tape at your disposal, and define your limits for each stage of your flow.

This step is not always easy to manage, especially when there are several groups as in this case. But once again, we must remain responsible for the frame! I then mainly made sure that the groups started to act rather than spending their time procrastinating.

Without throwing away the unused ingredients, I launch the second iteration.

After 5-7 minutes, the iteration ends and I invite the teams to calculate their score.

| Team A | Team B | |

| Round 1 | 18 | -12 |

| Round 2 | 36 | 93 |

| Round 3 | ||

| Round 4 |

The debriefing is particularly joyful in view of the results. Both teams have improved significantly during this iteration!

I then complete the iteration:

I leave you 2 minutes to think about your experience and make the changes that you think are wise for your system. Think about what worked well, what didn't work well, rebuild your workflow if needed, and adjust your limits.

Round 3: Introduce a constraint

This third round aims to add a little complexity to the game by introducing customer orders and above all a new pizza: the Rucola pizza!

You have gained popularity and you have decided to introduce a new pizza to your menu: the Rucola pizza. It consists of the same tomato base on which are placed 7 slices of rockets (green Post-it). However, be careful because arugula burns easily in the oven! It must therefore be added afterwards, when the pizza base is out of the oven.

After making sure that the instructions for this new pizza were well understood, I added:

You've had so much success that your customers are ordering from you. These usually include more than one slice of Hawaiian and/or Rucola pizza. Please note that you will only receive points if the entire order is filled!

I then give the team 2 minutes to prepare, develop their system and get organized, then I launch the third iteration.

After 5-7 minutes, the iteration ends and I invite the teams to calculate their score.

| Team A | Team B | |

| Round 1 | 18 | -12 |

| Round 2 | 36 | 93 |

| Round 3 | 26 | 12 |

| Round 4 |

By way of debriefing, we discuss the drop in productivity of each team where I quickly introduce the theory of constraints. I then specify that when a constraint is introduced into a system, there is an incompressible time necessary for the latter to re-stabilize, hence the observed drop in productivity.

Then I give the team 2 minutes to reflect on their experience of the round and make the appropriate changes for the next round.

Round 4: continuous improvement

This iteration is the last of the production iterations. It allows the team to experience continuous improvement following the introduction of a constraint in their system.

I give the team a few minutes to prepare and launch this final iteration.

After 5-7 minutes, the iteration ends and I invite the teams to calculate their score.

| Team A | Team B | |

| Round 1 | 18 | -12 |

| Round 2 | 36 | 93 |

| Round 3 | 26 | 12 |

| Round 4 | 101 | 135 |

The results are impressive! The improvement of the 2 teams is clear and without appeal, the system has adapted to the constraint while avoiding waste as much as possible!

I then draw an arrow from the results of Round 1 to Round 2, and one from the results of Round 3 to Round 4.

This then allows me to quickly introduce the theory of constraints:

The flow generated by a system is limited by at least one process.

Indeed, in the 2nd part of the workshop, we introduce a constraint in the process: the fact that the rucola burns in the oven!

The theory of constraints is implemented in 5 steps:

- Identify the constraint (the bottleneck)

- Exploit the constraint (maximize its use)

- Subordinate the system to the constraint

- Elevate Constraint Performance

- Start over at the first step if the constraint changes

What could be better than finishing on a touch of competition by calculating the final scores? 🙂

After some teasing from both teams, it was time to wrap up the workshop with the final wrap-up iteration.

Round 5: from the game to a real Kanban board

This last iteration is devoted to visualizing the production process used by the different teams in the form of a Kanban board.

For this latest iteration, I invite you to think back to your gaming experience and describe your production process and associated limitations on a sheet of flipchart. Feel free to use the ingredients produced during the game! Be creative! 🙂

After a few minutes (5-7 of course we get used to it!), I invite the participants to present their process to the other team and then we all quietly debrief together on what everyone learned during the workshop. 🙂

Conclusion

If you have 2 hours available and want to introduce the Kanban approach while having fun, the Kanban Pizza Game is the workshop for you! It is fun, complete and allows participants to live a learning experience, which – I guarantee you – will remain in their memories! 😉

One of my favorites at the moment! 🙂

7 responses

Hi Oliver,

Thank you for the additional info FR of this workshop which was useful to me.

Here is a little video following my workshop:

Hi Xavier,

Glad the article was helpful to you!

Thanks for sharing, the video is great! 🙂

With pleasure,

Olivier

Hello Oliver,

I played the pizza game with students of about 20 years old and I can't understand the non-drop in productivity between iteration 2 and 3 when introducing a constraint. Only one in four teams saw their productivity drop. Do you think it's because they didn't follow the instructions (they tended to cheat like kids!)? There were so many of them, I couldn't observe everything they were doing. I was also wondering if the creation of storage places that no longer allows to count the mess from iteration 2 was normal.

Thank you Olivier for the detail of your presentation. Do you have a recommendation for practicing the exercise in video (tools, good practice, etc.)?

Hello Benoit,

Sorry but I've never had to do it remotely yet. However, I think that if I were to lead a Kanban workshop, I would rather go on FeatureBan, but it's only a matter of preference 🙂

Now, if I were to actually do it remotely, I think a Miro/Mural might be enough to animate. The only potential difficulty is in coloring the tomato sauce because in physics, this red pen is a real visible bottleneck, whereas at a distance it may be more complicated to simulate. At the same time, you have to make good choices!

Good for you.

Olivier